The water mist generated in the spray tower needs to be treated to ensure the normal operation of the equipment and the safety of the environment. Common water mist treatment methods include the following:

1. Sedimentation tank treatment: The water mist in the spray tower is introduced into the sedimentation tank through the drainage pipe, and the suspended particles in the water mist are settled by gravity, and then the clear water is discharged. This method is suitable for the treatment of large particles.

2. Demister treatment: By installing a demister, the small particles in the water mist are captured to achieve the demist effect. Demisters can use different principles, including mesh demisters, spindle demisters, swirl demisters, etc. Mist eliminator treatment is suitable for the removal of small particulate matter.

3. Heavy liquid washing treatment: contact water mist with heavy liquid (such as sulfuric acid), and use the dissolution and adsorption of heavy liquid to absorb pollutants in water mist into heavy liquid, thereby realizing water mist treatment. This method is suitable for specific pollutant treatment, such as acid gas treatment.

4. Membrane separation treatment: Using membrane separation technology, the pollutants in the water mist are separated through the selective osmosis of the membrane, so as to realize the treatment of water mist. Membrane separation can choose different membrane materials and processes according to needs, which is suitable for the treatment of small particles and dissolved pollutants.

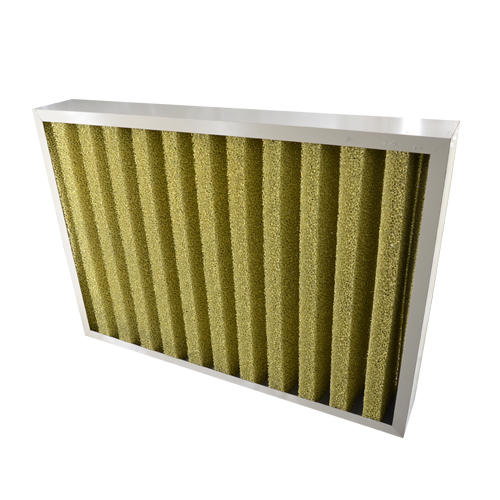

Select the appropriate water mist treatment method according to the actual situation, and conduct comprehensive treatment in combination with other purification equipment (such as dust collectors, washing towers, etc.) to meet the purification requirements. For the water mist of the spray tower, We specially designed a water mist removal filter, which is coated with a hydrophilic coating on the polyurethane sponge, supported by stainless steel brackets and outer frames. It can effectively stick the water droplets in the airflow to the filter screen. After the water droplets gather, they will flow downward under the action of gravity and be discharged from the orifice, so as to ensure that the initial resistance of the filter screen changes very little. Its main features:

1. High water removal efficiency, acid and alkali resistance;

2. W-shaped filter element design, small wind resistance;

3. It can be cleaned and used repeatedly, and the cost is low;

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters