The core components of the oil fume purifier are the flue and the purifier. When the flue gas enters the flue, it will be initially filtered through the pre-filter to remove some larger particles and grease. Then, the flue gas enters the main purification area, where the high-concentration oil mist is adsorbed and decomposed by the high-voltage electric field. Afterwards, the purified air is discharged through the post-filter. So what are the functions of the pre-filter and post-filter of the oil fume purifier?

●The pre-filter can effectively intercept and absorb most of the oil fume particles, prevent these particles from entering the oil fume purifier, prevent the oil fume purifier from clogging, and ensure the oil fume purification effect. Secondly, ensure that the oil fume purifier is not damaged by large friction objects and extend the service life of the oil fume purifier. At the same time, the pre-filter can also effectively remove part of the odor in the oil fume, reducing the smell of the oil fume and making the kitchen fresher.

●The post-filter usually adopts a filter cotton structure, which can intercept most of the 0.3 micron oil particles and prevent these oil particles from entering the flue, thus ensuring the normal use of the flue. At the same time, the rear filter can also prevent some small oil dirt from entering the hood and causing damage to the motor and other components.

The pre-filter and post-filter are important components of the oil fume purifier. Regular cleaning or replacement can effectively ensure the normal operation of the oil fume purifier, thereby ensuring the oil fume purification effect and protecting your health.

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters

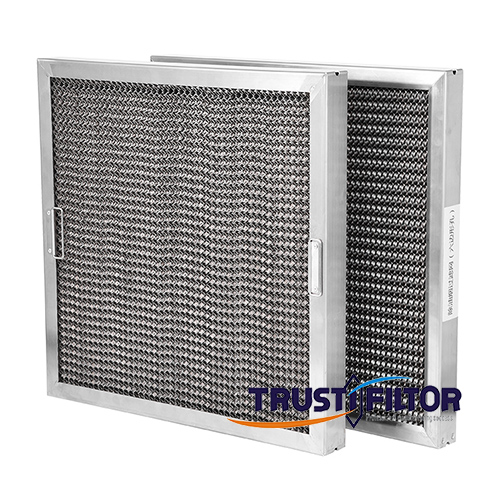

The difference between baffle grease filter and mesh grease filter

The difference between baffle grease filter and mesh grease filter