The oil fume filter uses mechanical or electrostatic adsorption to group and separate the oil fume exhaust gas, and electrically separates the oil fume particles to achieve the purpose of purifying the oil fume. It has a wide range of applications in the industrial field, mainly reflected in the following aspects:

● Factory and kitchen oil fume purifier: In factories and large kitchens, the generation of oil fume is the most important. Industrial oil fume filters, as stronger oil fume purification equipment, can effectively remove these oil fumes and protect the environment and workers' health. This is very important for improving the working environment, maintaining employee health, and enhancing corporate image and competitiveness.

● Air quality control: In some industrial environments where air quality needs to be controlled, the oil smoke filter also plays an important role. It can effectively filter out harmful substances such as oil smoke and dust in the air to ensure fresh air and environmental hygiene.

● Oil fume purification in catering industry: In catering, the generation of oil fume is also an important issue. The oil fume removal filter can effectively remove oil fume generated in catering establishments, improve the working environment in the kitchen, and also help reduce the impact of oil fume on the surrounding environment.

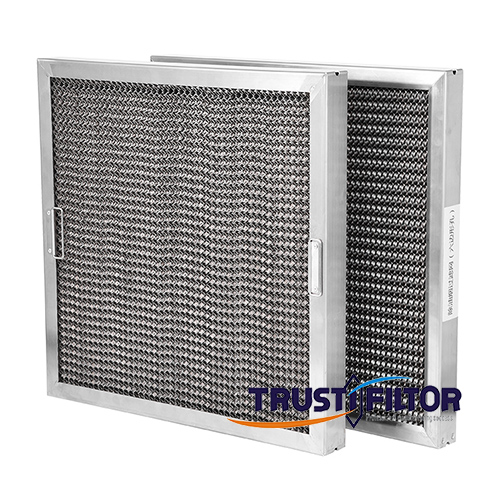

The material and structural design of the oil fume filter also make it suitable for various industrial applications. For example, high-efficiency filters are mainly made of glass fiber, ceramics, activated carbon and other materials. These materials can purify different types of oil fumes. At the same time, the multi-layer structure design also makes the oil fume removal filter have better filtration effect and service life.

In general, oil fume filters are widely used in the industrial field and are of great significance for improving environmental quality, protecting employee health, and enhancing corporate image and competitiveness.

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters

The difference between baffle grease filter and mesh grease filter

The difference between baffle grease filter and mesh grease filter