With the rapid development of modern society, more and more catering companies have begun to emerge. From large squares in the city to small towns in urban and rural areas, various restaurants and hotels are emerging one after another. While they are providing people with these mouth-watering delicacies, the problem of oil fume pollution also arises.

So what are the more common oil fume purifiers on the market? What are the advantages and disadvantages of each of them? Below we have specially compiled several common oil fume purifiers for you. Let’s take a look!

1. Mechanical centrifugation (full dynamic centrifugal oil fume separation and purification)

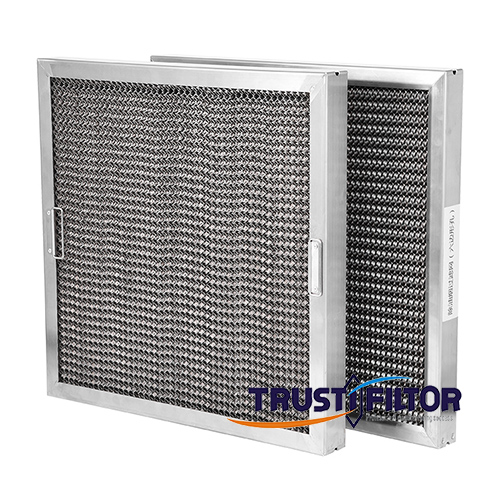

The first is the mechanical type. Common ones include centrifugal type (cyclone dust removal), filter type, partition type, etc., which uses mechanical centrifugation and adsorption filter materials to remove oil fume. The removal rate is high at the beginning, but the removal rate is very low in the later stage.Its operating cost is high, it requires frequent cleaning, maintenance is difficult, and it also produces secondary pollution.

2. Adsorption filtrationThe second is the adsorption filtration method. This purification method can generally only achieve a 90% oil fume purification rate and cannot be close to complete purification. It requires frequent replacement of filter layer materials and an increase in equipment.

3. Electrostatic (plasma) oil fume purification The third type is electrostatic oil fume removal, which is also the most widely used oil fume purification method with good purification effect in the oil fume purification industry. The plate purification efficiency reaches more than 80%.

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters