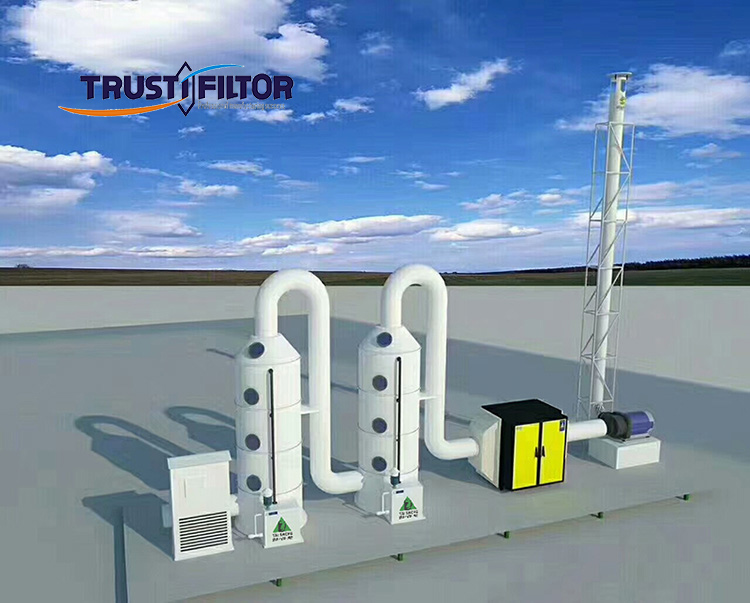

Spray tower is a common environmental protection equipment, mainly used to treat harmful substances in waste gas and waste water. Its working principle is to spray water into gas or liquid to reduce harmful substances to a concentration below safety standards, thereby achieving the purpose of purification. As a commonly used air treatment equipment, spray towers have a strong demand for removing water mist from the air. The following are some common methods for removing water mist in spray towers:

● Increase the height of the spray tower: Increasing the height of the spray tower can increase the time and impact of the contact between water mist and air, which helps the deposition and removal of water mist;

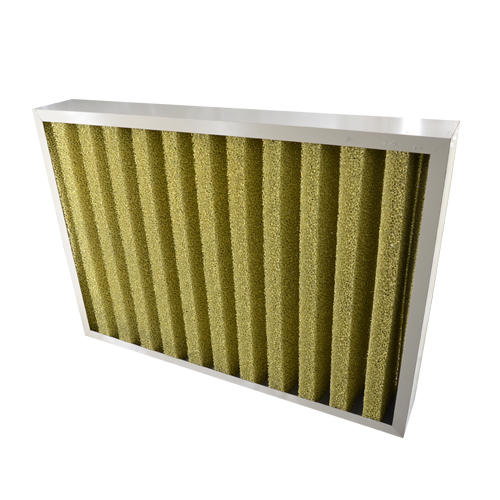

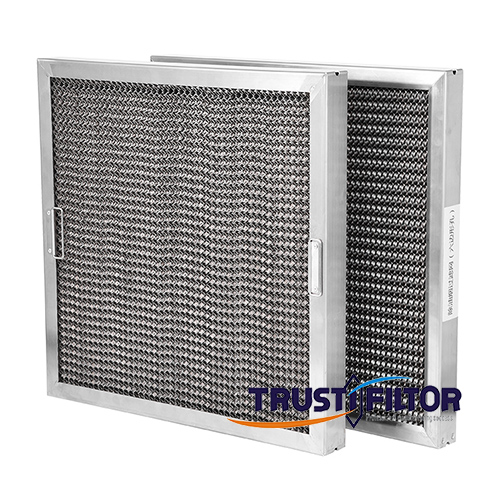

● Use a high-efficiency mist eliminator: Install a high-efficiency mist eliminator at the outlet or exhaust port of the spray tower to effectively remove water mist. High-efficiency mist eliminators usually use fiber, grid or mesh structures to capture water mist particles and deposit them.

Here we recommend an industrial water mist removal filter developed by Trustifiltor. It is a filter specially designed to control the water mist concentration ratio for the water mist at the end of the spray tower. By coating various water capture factors on different filter carriers, the proportion of gas moisture in the pipeline after passing through the filter can be effectively controlled.

● Optimize the spray water volume and nozzle design: Reasonably adjust the spray water volume and nozzle design of the spray tower to ensure that the water mist is evenly distributed and contacts the air to the greatest extent, and improves the removal efficiency of water mist;

● Control the air intake speed and humidity: Controlling the air intake speed can reduce the introduction of water mist, and controlling the air intake humidity can also help reduce the formation of water mist;

● Use chemical agents to assist in the removal of water mist: Adding an appropriate amount of chemical agents, such as surfactants, to the spray tower can enhance the deposition and aggregation effect of water mist and improve the removal efficiency;

● Regular maintenance and cleaning: Maintain and clean the spray tower regularly to remove blockages and accumulated water mist to maintain the normal working condition of the spray tower.

In short, it is necessary to select the appropriate water mist removal method according to the specific spray tower design and operation conditions to improve the mist removal effect and equipment performance.

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters