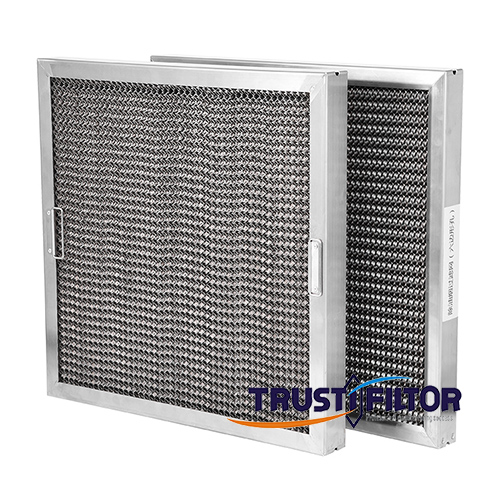

Steel mesh can be used to filter oil fume. Steel wire mesh is a metal mesh with high strength and corrosion resistance, usually made of stainless steel. Its mesh size can be adjusted as needed to adapt to the filtration requirements of different particles.

The application of steel wire mesh in oil fume filtration is usually as part of oil fume purification equipment, such as oil fume purifiers or oil fume collectors. When oil smoke passes through the steel mesh, the large particles in it will be blocked on the mesh, while the smaller particles and smoke will continue to pass through. Therefore, steel wire mesh is mainly used to filter large oil smoke particles, while for smaller particles or smoke, it may be necessary to combine with other filter materials or technologies for further purification.

As a commonly used oil fume removal equipment, steel wire mesh has the following main advantages and disadvantages:

Advantage:● High-efficiency filtration: Steel wire mesh has a fine mesh structure, which can effectively filter solid particles and grease in oil smoke, prevent them from entering the exhaust duct and indoor air, and reduce the impact of oil smoke on the environment and health.

● Strong durability: Steel wire mesh is usually made of stainless steel or other corrosion-resistant materials. It has high durability and corrosion resistance and can be used for a long time without being easily damaged.

Shortcoming:● Regular cleaning and maintenance are required: Since the steel mesh will gradually accumulate grease and dirt, if it is not cleaned for a long time, the ventilation effect will decrease and even cause blockage. Therefore, the steel wire mesh needs to be cleaned and maintained regularly to ensure its normal operation and filtration effect.

● Difficult to clean: The steel wires inside the steel mesh are intricate and oily smoke particles are easy to adhere to, making it difficult to clean. You can use clean water, detergent or special cleaning agent for cleaning to maintain the smoothness and filtering effect of the steel mesh.

It should be noted that the performance and effect of the oil fume filter are also affected by many factors, such as the mesh size of the steel mesh, filter design and maintenance, etc. Therefore, when selecting and using steel wire mesh for oil fume filtration, it needs to be evaluated and adjusted based on the specific circumstances and requirements.

How to set the filter of oil fume purifier

How to set the filter of oil fume purifier

The role of ozone removal filter in air purifier

The role of ozone removal filter in air purifier

What are the industrial applications of oil fume removal filters

What are the industrial applications of oil fume removal filters

Industrial applications of ozone removal filters

Industrial applications of ozone removal filters